Timing is Everything:

Readiness for Change + Great Minds = Making a Difference

How Urban Machine Began, Reclaiming Wood to Heal the Planet

Wood Waste is a Waste

Typically, wood is either burned or thrown into landfills–amassing 37 million tons of waste a year and accounting for 10% of all materials in landfills on an annual basis

The recycling rate for wood from construction and demolition (C&D) is extremely low, especially in comparison to other materials like concrete and steel–about 82% and 98%, respectively.

Urban Machine’s founders were outraged by how the construction industry discards its wood.

Idea Germination

Eric Law, Urban Machine’s CEO, was working for Swinerton as the Senior Director of Innovation when he first discovered the abundance of wood waste.

Studying sustainability for the company, he quickly wondered ‘Why can’t wood be recycled, too?’ Knowing that a problem is simply a chance to do something better, his brain whirred, looking for an opportunity for wood not to be wasted.

But how to do it??

Eric began investigating mass timber.

A Little Flashback

In the winter of 2020, Eric was researching the automation of mass timber installations for Swinerton. He was also working with a contracted robotics engineer (Andrew Gillies, founder of Dash Robotics) on a robot to install huge beams. They partnered well together and sparked each other’s creativity, but then, guess who showed up to stop the entire world?

Yep! You guessed it. COVID.

That nasty pandemic shut down all business – as we know – so, like everything else in the world, Eric and Andrew’s project just stopped.

Intention:

An Idea Born from Garbage

In the summer of 2021, the seed that had been planted – Eric’s new knowledge of how much wood is wasted from C&D – kept growing. Knowing that part of why wood is so under-recycled is that it’s too labor intensive to remove all of the nails and staples, he quickly wondered if a robot could be the answer.

Eric thought of Andrew and reached out to see if it was possible for a robot to extract so much metal from old wood to reclaim it for future use.

Timing is the Key

Just before Eric made that call, Andrew had left Dash to start freelance consulting for startups that were mostly in agriculture and construction. He was busy but not passionate. Eric’s idea enticed Andrew because this was close to his heart. Creating a robot that could reclaim wood was a project that would challenge Andrew and fit in his wheelhouse; he truly cares about sustainability and the environment.

Eric and Andrew went to construction sites to see the wood waste for themselves. The garbage invigorated them. It was quite apparent that if they could make this robot, they would be helping the industry and the planet.

Andrew got to work proving the concept so Eric could get busy selling that proof to investors. However, Andrew knew that he couldn’t do this without a great software engineer. Don’t worry. He knew a guy.

Another Little Flashback

The guy?

Alex Thiele. While a student at Arizona State University, Alex had visited a makers’ fair in San Francisco. He recognized a robotic design that he had learned about in one of his classes. He stopped to chat at that booth. The developer was none other than Andrew. They clicked.

After graduating from ASU, Alex moved to the Bay Area with a few friends, including his roommate Tyler. (Spoiler Alert! Remember Tyler; we will see him again on this blog.)

Timing Opens Another Door

One of Andrew’s friends had been a professor of Alex’s and kept touting Alex as a rockstar for his capabilities. The metaphorical neon lights were all pointing to Alex completing the triad of founders. But would Alex be interested in a job at another startup? Why would this be any different?

Well, unbeknownst to Andrew, Aotu – the startup where Alex was CTO – was starting to run out of money, and Alex was beginning to wonder if it was the right job for him. He liked the challenges of AI surveillance capabilities, but it didn’t seem like it would pan out in the long run.

Andrew called Alex, and, since the timing was right for him as well, the founders of Urban Machine became a real team.

However, Alex wasn’t starting this journey without a trusted software engineer – someone he knew would help them build the best robot to clean and reclaim wood into premium lumber.

Who Was the First Employee

at Urban Machine?

Yep. You remember him from earlier. Tyler Compton. Tyler was working as a Video Analytics Product Manager for Aotu. Seeing the good in what the founders were trying to accomplish, Tyler happily accepted the first opening at UM.

Lightening Fast

Urban Machine was formed in September of 2021. By October they had their terms sheet, and in November, they had closed their first round of funding – a helpful $1.7M – primarily from venture capitals Union Labs and Catapult Ventures, but money also came from angel investors Eric Klein and Shua Shachter.

#TeamWorkMakesTheDreamWork

With this capital, they made quick progress–a testament to how well the team works together. Within their first year, they have built three robots. The first, Awesome Ash, was focused on removing screws from wood. One major issue was that modern builders do not use screws in wood anymore (not since the 80’s). Even before they could adjust, while testing the robot at their warehouse, a giant pallet of lumber crashed into Awesome Ash upon delivery – annihilating her.

Movin’ & Groovin’

That’s when the guys at Urban Machine decided that The Machine needed to be mobile. This made it both greener and more cost (and user) effective while eliminating logistics issues in the warehouse.

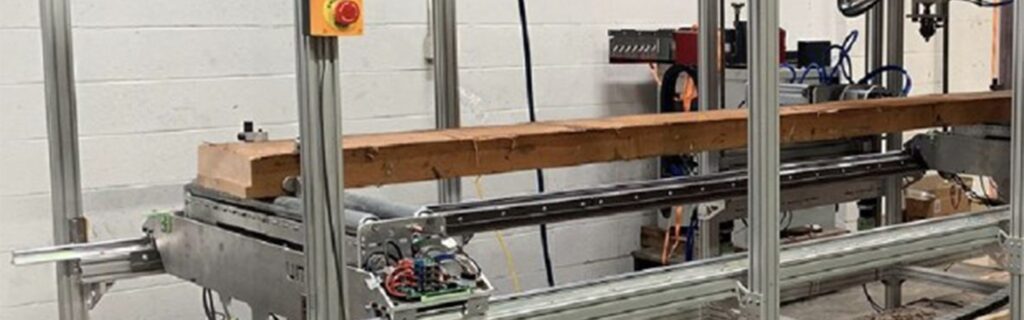

They finished Brave Baobab in March of 2022. This second iteration was focused on the shuttles that move the wood along. Continuing to learn quickly, the guys realized that these upgraded shuttles were causing headaches.

Smooth Move

In November of 2022, Charming Cypress got online. CiCi, for short, moves the wood along much more smoothly than Baobab did.

Ironically, the solution was less technical, but once the team let go of their beliefs, they were able to find the truth.

Using AI to pinpoint metals, The Machine removes bulk fasteners (nails, screws, and staples) and surface materials (like drywall) from reclaimed wood. Fasteners are pulled out of the wood using a powerful mechanism similar to that of a bird’s beak, hence its nickname Big Bird. Surface materials are removed using rotating wire brushes–like a carwash for wood! Finally, The Machine performs a quality check to ensure the wood is ready for new construction.

Timing is everything. If it’s supposed to happen, it will.

At the right time.

At the right place.

For the right reasons.